PVC Coated Trim Coated Aluminum Coil Decoiling 200MM 2600 Mm For Construction

Product Details:

| Place of Origin: | Shanghai |

| Brand Name: | Alumetal |

| Model Number: | AM015 |

Payment & Shipping Terms:

| Price: | To be negotiated |

|---|---|

| Packaging Details: | Packing: Packing in bulk; Packing in wooden fumigated pallets; Packing as customer requests |

|

Detail Information |

|||

| Product Name: | Color Coating Aluminum Coil 1100 5005 For Construction | Application: | Roofing Interior Exterior Wall Decoration,facade, Roofing, Interior And Exterior Wall Decoration, Facade, ACP, Etc |

|---|---|---|---|

| Temper: | O - H112 | Tolerance: | ±1% |

| Processing Service: | Bending, Decoiling, Welding, Punching, Cutting | Aluminum Alloy: | Aluminium (AA1100, 3003, 3004, 3105, 5006, 5052, 8011, Etc) |

| Standard Width: | <2600 Mm | Coil Thickness: | 0.06~1 Mm |

| Coating: | PE/PVDF/FEVE | Feature: | Durability, High Erosion Resistance, Abrasion Resistance, Etc |

| Highlight: | Coated Aluminum Coil Decoiling 200MM,Coated Aluminum Coil 2600 mm,pvc coated trim coil For Construction |

||

Product Description

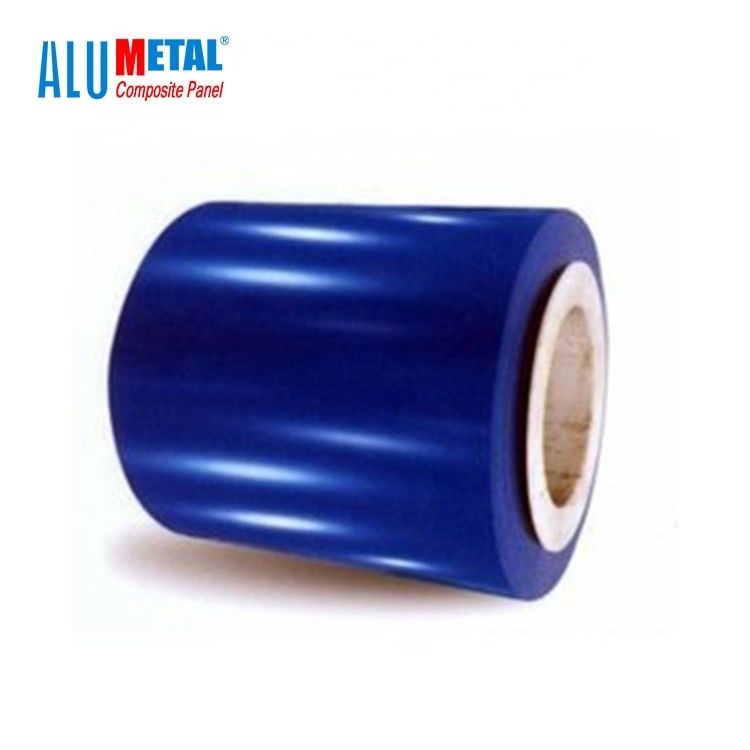

Color Coating Aluminum Coil 1100 5005 For Construction

First, The Raw Material Coil Input, Is The Uncoiler Continuous Rewinding To Ensure Continuous Transmission Of The Coil With A Stable Inputting To Production Line. Second, Surface Cleaning And Chemical Treatment, Is To Clean And Chemical Pretreatment The Top And Bottom Faces Of The Aluminum Coil In Order To Ensure That The Paint Can Be Firmly Attached The Coil. The Third Is Painting. Each Production Line Should Have At Least Two Roller Coating Machine To Ensure Prime And Top Coats Can Be Two Layers Coated. Forth Is The Paint Layer Curing That Is The Roll Coil Which Is Finished Painted Just Now Should Be Completed Curing Before Touch The Next Roller To Avoid Mutual Adhesion And Destruction. Generally, It Has At Least Two Curing Boxes In A Production Line. Fifth, Refers To Finished Products Output. It Should Ensure The Production Line’s Speed And Finished Coil Transfer Synchronization.

| Alloy | Thickness | Width | Temper |

| A1050, A1060, A1070, A1100 | 0.2MM~200MM | 10MM~2500MM | O, H12, H22, H14, H16, H18, H24, H26, etc |

| A3003, A3105, A3004 | 0.2MM~200MM | 10MM~2500MM | O, H14, H18, H24, etc |

| A5052, A5005, A5083, A5754 | 0.2MM~200MM | 10MM~2500MM | O, H14, H18, H24, etc |

| A6061, A6082, A6063 | 0.2MM~200MM | 10MM~2500MM | T4, T6, T651, etc |

| A8011 | 0.2MM~200MM | 10MM~2500MM | O, H12, H22, H14, H16, H18, H24, H26, etc |

| Production Process | Cold Rolled, Hot Rolled |

| Internal Diameter | 150mm, 305mm, 405mm, 505mm or per request |

| Coil Weight | 2-4 tons |

| Standard | ASTM-B209, EN573-1, GB/T3880.1-2006 |

| Color | Alumetal color and customized color as sample, Ral or Pantone |

| Color Standard | E<2 or it is not obvious by eyeballing |

| Coating | PE, PVDF, Epoxy |

| Coating Thickness | PVDF>=25 micron POLYESTER>=18 micron |

| Coating Adhesive | Not lower than first grade impact: no any crack (50kg/cm, ASTM D-2794:1993) |

| MOQ | 5~8 Tons (According to specification) |

| Delivery Time | Future goods: 20~30 work days, ready stock: 7-10 days. |

| Quality of Material | Totally free from detects like white rust, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set. |

| Pencil Hardness | >2HB |

| Bend Strength | >100 times |

| Boiling Point | No any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

| Corrosive | Surface deep in the 5% muriatic acid and 5% NaCl, interior deep in the 2% muriatic acid and 2% NaCl, after 48 hours, no change |

| Package | Export wooden pallets, craft paper. The bundle weight not exceed 2 MT, Loading: by 1x20GP |

Click Below to Download Color Chart

Alumetal Color Chart.pdf

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Q1. What is the minimum order quantity?

500Sq M for aluminium composite panel for one color with 1220 mm*2440 mm size.

Q2. What is your terms of payment?

T/T 30% deposit in advance; the balance paid should be paid according to the copy of B/L.

Q3. How about your delivery time?

Generally, it will take 15to 20days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings.

Q5. Why can I trust you and place order with you?

1. We are manufacture and supplier of aluminum composite panel in china with over 10 years's experience.

2. We keep fastest delivery. Since we have perfect production equipment.